Are your disconnected systems quietly draining profitability?

In manufacturing and distribution, every hour of production time matters. Every inventory decision impacts cash flow. Every order fulfilled shapes customer satisfaction. Yet for many companies, the systems that should enable efficiency are actually creating costly inefficiencies—not through dramatic failures, but through quiet, systematic erosion of profitability that often goes unnoticed until it's too late.

According to recent industry research, businesses with disconnected systems lose 20-30% of their revenue annually to poor data quality and fragmented processes. For a mid-sized manufacturer with $50M in annual revenue, that represents $10-15 million lost every year to preventable inefficiencies.

The culprit? Data silos. Disconnected ERPs. Fragmented technology stacks where critical business information lives in isolated systems that don't communicate. While each system may work fine independently, the lack of integration creates a cascading series of problems that compound over time.

This article explores the hidden costs of disconnected ERP systems in manufacturing and distribution—and shows you how integrated workflows can transform these costly inefficiencies into competitive advantages.

Table of Contents

- Understanding Disconnected ERP Systems

- The State of Manufacturing Technology in 2026

- The 10 Hidden Costs of Disconnected ERP Systems

- Cost 1: Manual Data Entry and Reconciliation

- Cost 2: Delayed Decision-Making

- Cost 3: Inventory Inaccuracies

- Cost 4: Production Delays and Downtime

- Cost 5: Order Errors and Customer Dissatisfaction

- Cost 6: Duplicated Efforts and Wasted Time

- Cost 7: Compliance and Regulatory Risks

- Cost 8: Stifled Innovation

- Cost 9: Strategic Blind Spots

- Cost 10: Scalability Limitations

- The True Cost: A Manufacturing Case Study

- Why Integration Is the Answer

- The Integrated ERP Architecture

- Real-World Integration Success Stories

- Building the Business Case for Integration

- How SyncMatters Helps Manufacturing & Distribution Companies

- Implementation Roadmap

- Conclusion

Understanding Disconnected ERP Systems

Before exploring costs, let's define what we mean by "disconnected ERP systems."

A disconnected ERP environment occurs when:

- Multiple software systems operate independently without real-time data exchange

- Information must be manually transferred between platforms

- Different departments use different systems that don't communicate

- Data exists in multiple versions across various platforms

- Critical business processes require human intervention to bridge system gaps

Common Scenarios in Manufacturing & Distribution

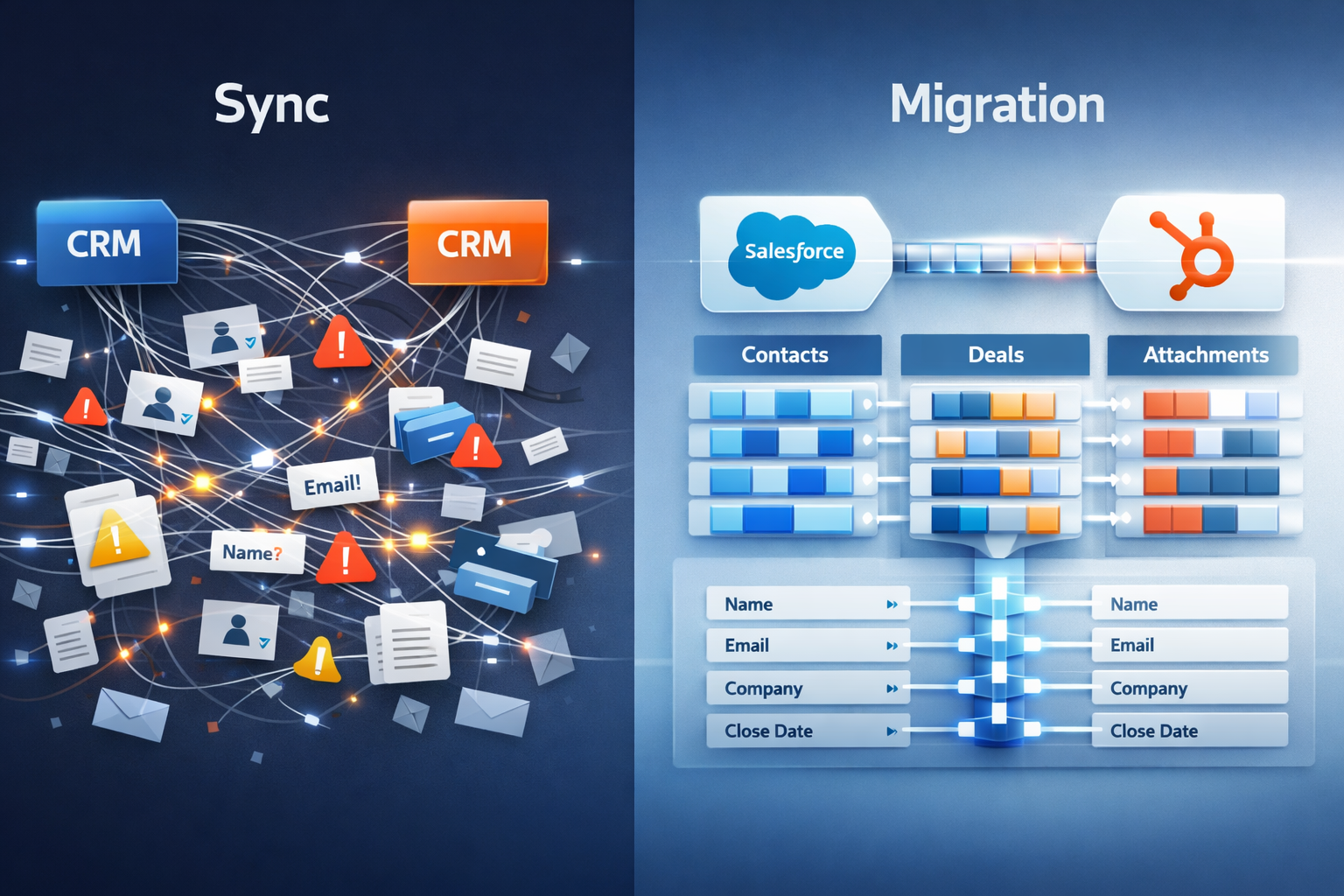

Scenario 1: The CRM-ERP Disconnect

Sales closes deals in a CRM like HubSpot or Salesforce, but production planning happens in an ERP like SAP, NetSuite, or Sage X3. Orders must be manually re-entered, leading to delays, errors, and frustrated customers.

Scenario 2: The Shop Floor Data Gap

Production data from MES (Manufacturing Execution Systems) or SCADA doesn't flow automatically into the ERP. Managers lack real-time visibility into work-in-progress, leading to missed deadlines and poor resource allocation.

Scenario 3: The Inventory Blind Spot

Warehouse management systems (WMS) operate separately from procurement and financial systems. Inventory counts don't match across platforms, resulting in stockouts, overstock, and inaccurate financial reporting.

Scenario 4: The Finance-Operations Divide

Operations teams use one set of tools while finance uses QuickBooks, Xero, or another accounting platform. Month-end close requires days of manual reconciliation as teams struggle to align operational data with financial records.

Scenario 5: The Supply Chain Silo

Supplier portals, logistics tracking, and procurement systems don't integrate with the core ERP. Supply chain disruptions aren't visible until they cause production delays.

Why Disconnection Happens

Data silos typically arise from:

- Legacy systems: Older platforms that predate modern integration capabilities

- Organic growth: Companies acquire new tools as needs evolve without considering integration

- Departmental autonomy: Different teams select their own solutions independently

- Cost avoidance: Viewing integration as an "optional" expense rather than essential infrastructure

- Technical limitations: Lack of APIs or integration capabilities in older systems

- Resource constraints: Limited IT budgets, expertise, or time to implement proper integration

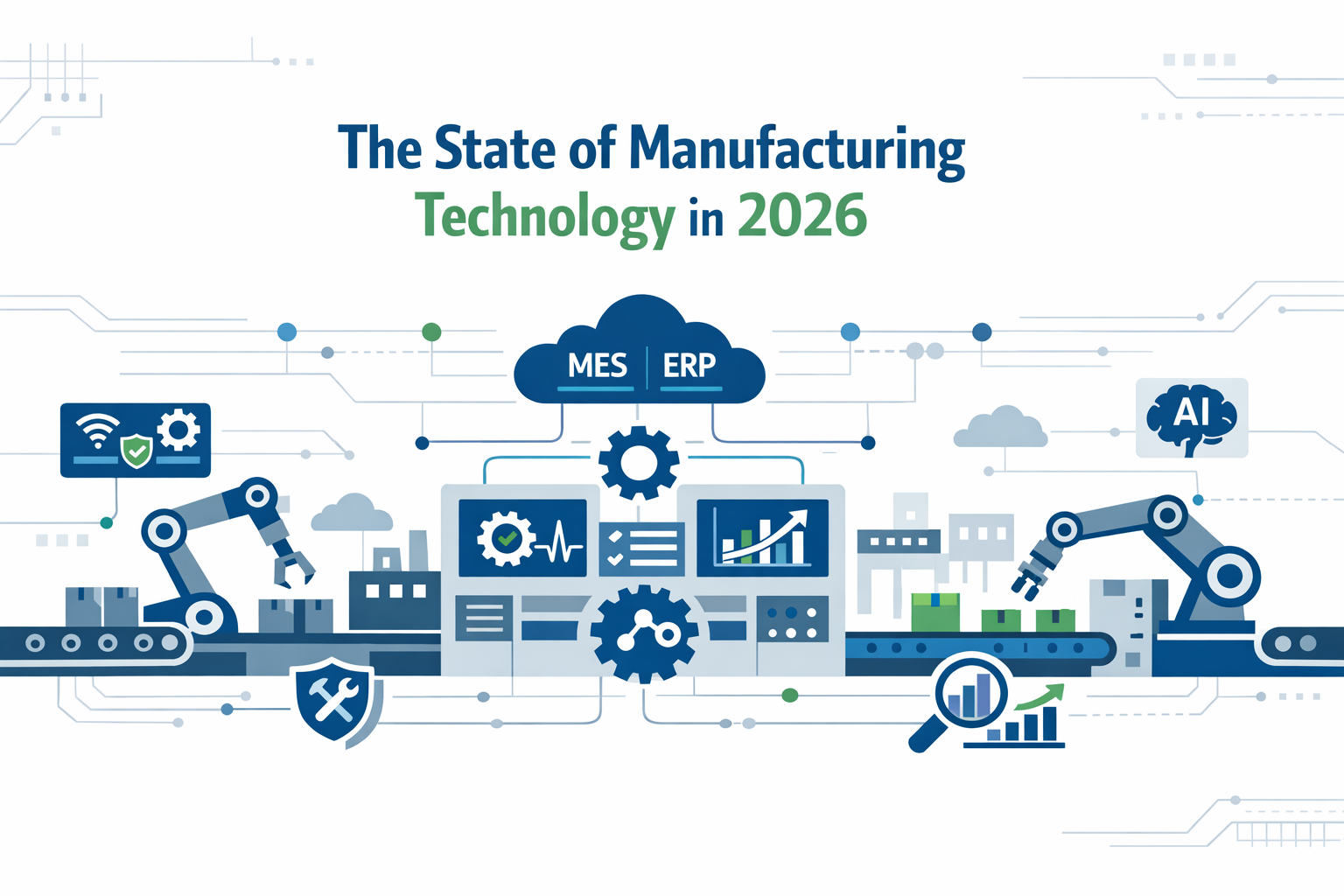

The State of Manufacturing Technology in 2026

To understand the disconnect problem, it's important to recognize the complexity of modern manufacturing technology stacks.

The Typical Manufacturing Technology Ecosystem

| Category | Common Systems | Data Generated |

|---|---|---|

| ERP Core | SAP, Oracle, NetSuite, Sage X3, Epicor, Infor | Financials, orders, materials, production schedules |

| CRM | Salesforce, HubSpot, Zoho, Pipedrive | Opportunities, customer data, quotes, contacts |

| MES / Shop Floor | Rockwell, Siemens, GE Digital, Plex | Real-time production, quality, equipment status |

| WMS / Inventory | Manhattan, Blue Yonder, Fishbowl | Stock levels, locations, movements |

| Quality Management | ETQ, Sparta, MasterControl | Inspections, non-conformances, corrective actions |

| Supply Chain | Blue Yonder, Kinaxis, SAP Ariba | Supplier performance, logistics, procurement |

| CAD / PLM | Autodesk, Dassault, PTC | Engineering data, BOMs, change orders |

| Accounting | QuickBooks, Xero, Sage, Oracle Financials | GL, AP/AR, payroll, cost accounting |

| Business Intelligence | Tableau, Power BI, Qlik | Analytics, dashboards, reporting |

| IoT / Sensors | Various proprietary systems | Machine data, environmental conditions |

According to recent research, businesses use an average of 1,061 applications, but only 29% are integrated. This fragmentation creates the foundation for hidden costs that compound over time.

Market Dynamics Driving Change

- 47% of ERP users are in manufacturing, the largest segment

- The global ERP market will surpass $115 billion in 2026, growing to $199.6 billion by 2030

- 41% of organizations now use cloud-based ERP systems, up from predominantly on-premise deployments

- 85% of ERP vendors are incorporating AI features that require unified data to function effectively

- ERP cost overruns affect 57% of projects, often due to underestimated integration complexity

The 10 Hidden Costs of Disconnected ERP Systems

Cost 1: Manual Data Entry and Reconciliation

The problem:

When systems don't communicate, humans become the integration layer. Staff manually re-enter data from one system into another—orders from CRM to ERP, production data from shop floor to financial systems, inventory counts from warehouse to accounting.

The time drain:

A 2024 study found that businesses using disconnected legacy systems spent up to 30% more time reconciling financials compared to those using integrated cloud ERP solutions. For manufacturing companies, employees waste 8-12 hours weekly on redundant data entry.

The financial impact:

| Company Size | Staff Affected | Hours/Week | Hourly Cost | Annual Cost |

|---|---|---|---|---|

| Small (50 employees) | 10 staff | 10 hours each | $30/hour | $156,000 |

| Mid-size (200 employees) | 40 staff | 10 hours each | $35/hour | $728,000 |

| Large (500 employees) | 100 staff | 10 hours each | $40/hour | $2,080,000 |

Beyond the numbers:

Manual data entry isn't just costly—it's soul-crushing work that drives employee dissatisfaction and turnover. Your talented staff members joined to contribute meaningfully, not to copy-paste data between spreadsheets.

Cost 2: Delayed Decision-Making

The problem:

Effective operational decisions depend on current, accurate data. When teams work with outdated or incomplete information pulled from separate systems, they cannot react swiftly to supply chain disruptions, quality control issues, or shifts in customer demand.

The visibility gap:

According to research, disconnected systems delay corrective actions and thorough root-cause analysis. Organizations with siloed data reportedly take five times longer to generate cross-functional insights.

Real-world consequences:

- Production managers can't adjust schedules because they don't have real-time material availability

- Purchasing can't optimize orders because they lack visibility into actual consumption rates

- Leadership can't capitalize on market opportunities because data compilation takes days or weeks

- Customer service can't resolve issues quickly because they need to check multiple systems

The competitive disadvantage:

In today's fast-moving markets, the company that can make informed decisions fastest wins. Disconnected systems transform what should be competitive advantages—data and analysis capabilities—into competitive liabilities.

Cost 3: Inventory Inaccuracies

The problem:

When materials aren't tracked consistently across all systems, inventory data becomes unreliable. The ERP shows one stock level, the WMS shows another, and the shop floor has a third version of reality.

The cascading effects:

Over-ordering waste:

- Purchasing orders materials that already exist in another location

- Cash tied up in unnecessary inventory

- Storage costs for excess materials

- Risk of obsolescence before materials are used

Under-ordering disruption:

- Production delays when materials run out unexpectedly

- Expedited shipping fees to rush-order missing components

- Overtime costs to recover lost production time

- Customer delivery delays damaging relationships

Financial reporting errors:

- Inventory valuations don't match physical counts

- Cost of goods sold calculations are inaccurate

- Financial statements mislead decision-makers

- Month-end close requires extensive reconciliation

Industry data:

Retailers and distributors increasing inventory accuracy by 80% after implementing integrated ERP report significant improvements in both cash flow and customer satisfaction.

Cost 4: Production Delays and Downtime

The problem:

Without real-time visibility into machines, production progress, and material availability, manufacturers experience preventable delays that directly impact throughput and profitability.

The downtime cost:

Studies show a single hour of downtime in manufacturing can cost between $10,000 to $500,000 depending on the industry and operation size. For oil and gas operations specifically, one hour can cost nearly $500,000, with average operators losing about $149 million per year to unplanned outages.

Common delay scenarios:

| Delay Cause | Root Issue | Impact |

|---|---|---|

| Material shortages | Inventory system didn't trigger reorder | 2-4 hours downtime per incident |

| Equipment failures | Maintenance data not integrated with production planning | 4-12 hours downtime + repair costs |

| Quality holds | QC results not immediately visible to production | 1-3 hours per batch affected |

| Schedule conflicts | Different systems showing different priorities | Missed deadlines, overtime costs |

Preventable vs. actual:

Industry research reveals that 30-40% of production delays are directly attributable to information gaps between disconnected systems—delays that would be eliminated with proper integration.

Cost 5: Order Errors and Customer Dissatisfaction

The problem:

When sales, production, and fulfillment systems don't communicate seamlessly, orders get lost, misconfigured, or delayed—resulting in disappointed customers and damaged relationships.

Order error types:

Configuration mistakes:

- Sales promises features the shop can't produce

- Custom specifications don't transfer correctly from CRM to production

- Engineering changes aren't reflected in active orders

Fulfillment failures:

- Wrong products shipped because inventory data was inaccurate

- Delivery dates missed because production wasn't aware of commitments

- Partial shipments when warehouse doesn't have complete visibility

Billing discrepancies:

- Invoices don't match purchase orders due to system disconnects

- Change orders approved but not reflected in billing

- Payment delays while customers dispute inaccurate invoices

The ripple effect:

A single order error doesn't just cost the immediate fix—it damages customer trust, generates negative reviews, requires additional customer service time, and often results in discounts or concessions to repair the relationship.

Customer retention impact:

Research shows that 71% of business leaders cite the disconnect between engineering, design, and manufacturing teams as a primary barrier to innovation and customer satisfaction.

Cost 6: Duplicated Efforts and Wasted Time

The problem:

When critical information doesn't flow between departments, teams often duplicate work or repeat mistakes. If a process engineer's findings on a recurring equipment issue never reach the maintenance planner, the same troubleshooting may be done repeatedly.

Common duplication scenarios:

- Multiple departments creating their own reports from different data sources

- QA inspections repeated because previous results weren't visible

- Engineering solving problems that operations had already addressed

- Sales creating custom quotes for configurations that already exist

The efficiency drain:

According to data silo research, disconnected information seriously affects work efficiency, with teams frequently spending time reconciling inconsistent figures and re-collecting data that already exists elsewhere.

The innovation cost:

Time wasted on duplicate work is time not spent on value-creating activities like process improvement, new product development, or customer relationship building.

Cost 7: Compliance and Regulatory Risks

The problem:

Manufacturing and distribution face strict regulatory requirements—FDA, FSMA 204, ISO certifications, environmental regulations, and more. Disconnected systems make compliance exponentially more difficult and risky.

Specific compliance challenges:

Traceability requirements:

The FSMA 204 Traceability Rule requires companies to track Key Data Elements (KDEs) and Critical Tracking Events (CTEs) across their supply chain. With siloed systems, gathering audit-ready records is nearly impossible.

Lot genealogy:

Manufacturers need complete traceability from raw materials to finished goods. When data lives in multiple systems, reconstructing the chain of custody for a specific lot becomes a manual, error-prone process.

Environmental reporting:

Sustainability and circular economy workflows demand precise material traceability and energy data capture to accurately measure carbon footprint and waste. Disconnected systems prevent accurate measurement.

Audit readiness:

When auditors arrive, companies with siloed systems face weeks of manual data compilation to produce required documentation. Integrated systems provide audit-ready reports instantly.

The financial risk:

| Compliance Issue | Potential Cost Range |

|---|---|

| FDA warning letter | $10,000 - $50,000+ (remediation) |

| Product recall | $500,000 - $10M+ |

| Environmental violation | $5,000 - $500,000 per incident |

| Failed audit / lost certification | Loss of customers, contracts |

| Legal liability | Variable, potentially millions |

Cost 8: Stifled Innovation

The problem:

The disconnect between engineering, design, and manufacturing teams is a primary barrier to innovation. This lack of synergy, which worries 71% of business leaders, prevents the collaborative feedback loop needed to improve product design and accelerate time-to-market.

Innovation blockers:

Slow feedback loops:

When production issues aren't immediately visible to design engineers, design flaws persist through multiple production runs before corrections happen.

Missed opportunities:

Field service data about product failures doesn't reach engineering teams who could prevent issues in next-generation designs.

Resource misallocation:

Without unified visibility, R&D invests in solving problems that operations has already addressed, or ignores critical issues causing production headaches.

Market responsiveness:

Competitors with integrated systems can iterate faster, respond to market changes quicker, and launch new products ahead of companies hampered by disconnected workflows.

The competitive reality:

According to Hexagon's research, 98% of manufacturers face data-related issues that directly stifle innovation and slow their time-to-market. Companies that eliminate these silos can innovate 2-3x faster than competitors still struggling with disconnected systems.

Cost 9: Strategic Blind Spots

The problem:

Leadership makes decisions based on incomplete information because comprehensive data views require manual compilation from multiple systems. By the time reports are ready, market conditions have changed.

The executive experience:

In many companies, leaders describe their reality like this:

- "I get a monthly production report—but it's stale by the time I read it"

- "I cross-check three Excel files just to see if we're losing margin"

- "I can't quickly pinpoint supply chain bottlenecks"

Missing insights:

| Strategic Question | Why Disconnected Systems Can't Answer |

|---|---|

| Which products/customers are most profitable? | Cost data in ERP, revenue in CRM, production efficiency in MES—no unified view |

| Where are our biggest operational inefficiencies? | Data scattered across systems without correlation |

| How do supply chain disruptions impact delivery commitments? | Supplier data, production schedules, and customer orders in separate systems |

| What's our true capacity for growth? | No unified view of equipment utilization, labor capacity, and market demand |

The opportunity cost:

McKinsey reports that companies with unified data systems are 1.5 times more likely to outperform competitors in making data-driven decisions. Disconnected systems don't just delay decisions—they lead to wrong decisions based on incomplete information.

Cost 10: Scalability Limitations

The problem:

As companies expand product lines, add facilities, or acquire other businesses, disconnected systems become increasingly unmanageable. What was merely inefficient at small scale becomes completely untenable at larger scale.

Growth bottlenecks:

Geographic expansion:

Opening new locations requires replicating disconnected systems or attempting to standardize across sites with incompatible technologies.

Product line expansion:

Each new product category adds complexity that disconnected systems can't handle efficiently.

Mergers and acquisitions:

Integrating an acquired company's systems with your fragmented architecture creates exponential complexity.

Capacity constraints:

Without unified visibility, companies can't confidently take on larger orders because they don't know their true capacity.

The scale reality:

Many Pack Expo attendees shared that Excel sheets and legacy systems simply cannot keep up with growth, creating a bottleneck between opportunity and execution.

The True Cost: A Manufacturing Case Study

To make these hidden costs concrete, let's examine a composite case based on real implementation data.

Company Profile

- Industry: Custom metal fabrication

- Size: 175 employees

- Revenue: $45 million annually

- Locations: 2 manufacturing facilities

- Technology stack: 12 disconnected systems

Initial State: The Disconnected Reality

Systems landscape:

- ERP: Legacy on-premise system (15 years old)

- CRM: Salesforce (operated independently by sales team)

- Shop floor: Paper-based tracking with end-of-shift manual data entry

- Inventory: Separate WMS not integrated with ERP

- Quality: Spreadsheet-based tracking

- Accounting: QuickBooks (separate from ERP for financial reporting)

Quantified Hidden Costs (Annual)

| Cost Category | Annual Impact | Calculation Basis |

|---|---|---|

| Manual data entry & reconciliation | $312,000 | 15 staff × 10 hours/week × $40/hour × 52 weeks |

| Inventory inaccuracies | $225,000 | Overstock carrying costs + expedited shipping + stockout sales loss |

| Production delays | $180,000 | 12 hours/month downtime × $15,000/hour |

| Order errors & rework | $135,000 | 8% order error rate × $1.69M monthly orders |

| Duplicated efforts | $90,000 | Redundant reporting, repeated troubleshooting |

| Delayed billing | $67,500 | 15-day average delay × opportunity cost of capital |

| Compliance risk | $45,000 | Additional audit preparation, near-miss incidents |

| Strategic missed opportunities | $200,000+ | Conservative estimate of lost sales/optimization |

| Total Annual Hidden Cost | $1,254,500 | 2.8% of revenue |

After Integration: The Transformation

The company partnered with SyncMatters to implement comprehensive ERP integration connecting:

- Salesforce CRM ↔ ERP (bidirectional)

- Shop floor data collection → ERP (real-time)

- WMS ↔ ERP (real-time inventory sync)

- Quality system → ERP (automated tracking)

- QuickBooks ↔ ERP (financial reconciliation)

Implementation:

- Timeline: 16 weeks

- Investment: $85,000 (integration) + $15,000 (training) = $100,000 total

- Approach: Phased deployment minimizing disruption

Results after 12 months:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Manual data entry hours/week | 150 hours | 22 hours | 85% reduction |

| Inventory accuracy | 82% | 98% | 16 percentage points |

| Average production delay/month | 12 hours | 2 hours | 83% reduction |

| Order error rate | 8% | 1.2% | 85% reduction |

| Days to close books | 8 days | 2 days | 75% reduction |

| On-time delivery rate | 78% | 94% | 16 percentage points |

Financial impact:

- Hidden costs reduced: $1,003,600 (80% reduction)

- New revenue from capacity gains: $450,000

- Total annual benefit: $1,453,600

- ROI: 1,354%

- Payback period: 4.1 weeks

Why Integration Is the Answer

The solution to disconnected ERP systems isn't replacing everything—it's connecting what you have.

The Integrated Approach

Rather than attempting a complete ERP replacement (expensive, risky, time-consuming), modern integration strategies focus on:

1. Connecting existing systems

Use middleware and APIs to enable real-time data exchange between current platforms.

2. Establishing a single source of truth

Define which system owns each data element and ensure all others sync to that authoritative source.

3. Automating data flows

Eliminate manual data entry through automated synchronization triggered by business events.

4. Enabling real-time visibility

Create dashboards pulling live data from all connected systems for comprehensive operational views.

5. Building scalable architecture

Design integration frameworks that accommodate future system additions or replacements without starting over.

The Business Benefits

According to industry research:

- Businesses with integrated systems save 20-25% on operational costs compared to those with siloed data (Deloitte)

- Manufacturers with integrated data systems are 2.5 times more likely to achieve cost and time efficiencies (Deloitte)

- Companies implementing proper integration solutions see 30% improvement in productivity and 15% reduction in time-to-market (Forrester)

- ERP systems integrated with IoT improve supply chain efficiency by 35% (industry statistics)

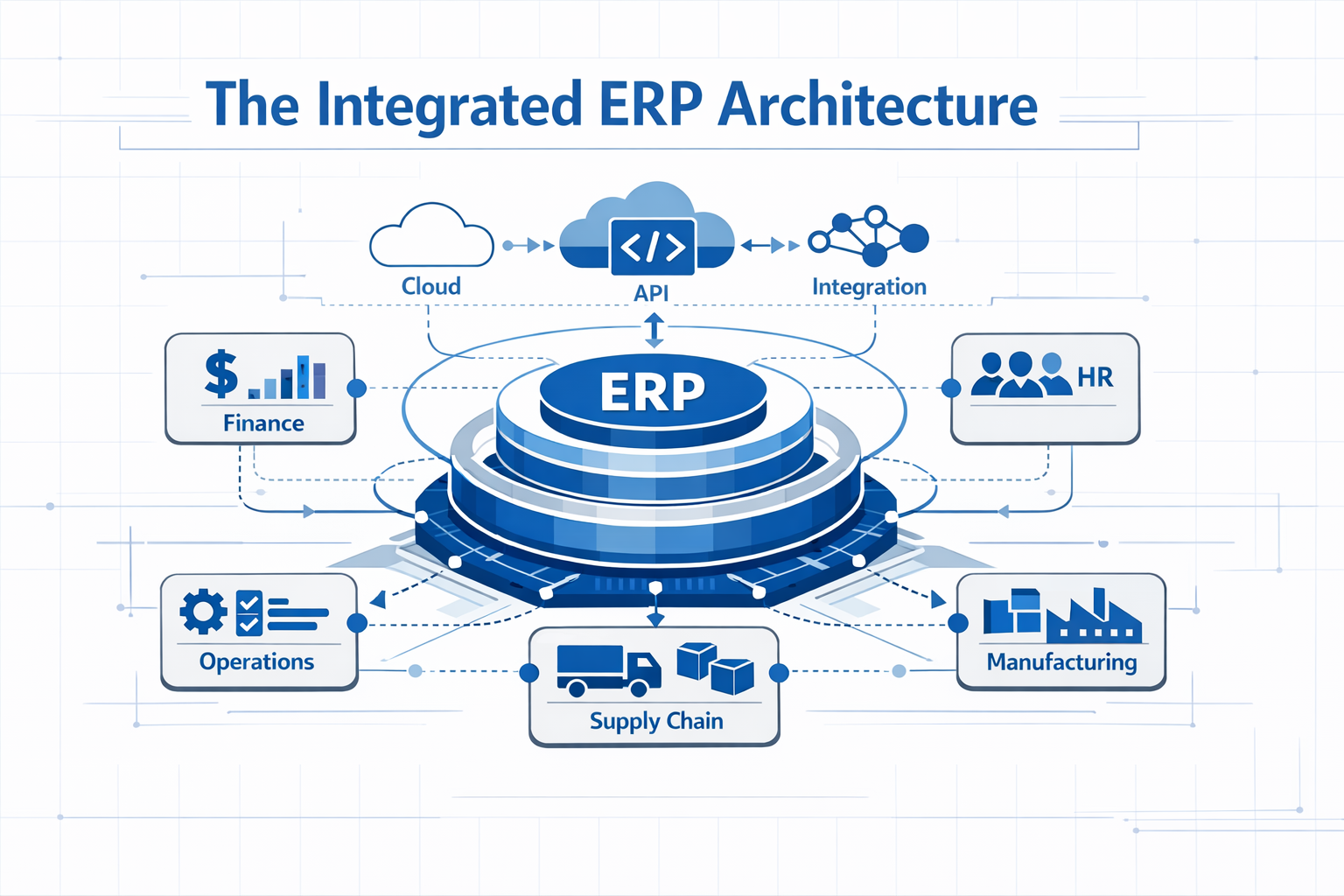

The Integrated ERP Architecture

Core Integration Patterns

Pattern 1: Hub-and-Spoke

The ERP serves as the central hub with all other systems connecting to it. This simplifies architecture and ensures the ERP remains the system of record for core business data.

Pattern 2: Point-to-Point with Middleware

Critical systems connect directly to each other through an integration platform (iPaaS) that manages data transformation, error handling, and monitoring.

Pattern 3: Event-Driven Architecture

Business events (order placed, production completed, quality check failed) trigger automated workflows across connected systems.

Essential Integration Points for Manufacturing

| Integration | Systems Connected | Data Flow | Business Value |

|---|---|---|---|

| CRM ↔ ERP | Salesforce/HubSpot ↔ SAP/NetSuite | Opportunities, orders, customer data | Eliminate order re-entry, real-time visibility |

| MES → ERP | Shop floor systems → ERP | Production data, equipment status | Real-time production visibility, accurate costing |

| WMS ↔ ERP | Warehouse management ↔ ERP | Inventory movements, stock levels | Accurate inventory, prevent stockouts |

| QMS ↔ ERP | Quality management ↔ ERP | Inspections, non-conformances | Compliance tracking, lot traceability |

| ERP ↔ Accounting | ERP ↔ QuickBooks/Xero | GL transactions, AP/AR | Fast month-end close, accurate financials |

| PLM → ERP | CAD/PLM systems → ERP | BOMs, engineering changes | Accurate production planning, change control |

| Supply Chain ↔ ERP | Procurement/logistics ↔ ERP | POs, shipments, supplier data | Supply chain visibility, vendor performance |

Integration Technology Stack

Integration Platforms (iPaaS):

- SyncMatters - Specialized in manufacturing and CRM integration

- Zapier / Make - For simpler workflows

- MuleSoft / Boomi - Enterprise-grade platforms

- Dell Boomi / Workato - Mid-market solutions

API Management:

- RESTful APIs for modern cloud applications

- SOAP/XML for legacy system connectivity

- GraphQL for flexible data querying

- Webhooks for event-driven triggers

Data Transformation:

- ETL (Extract, Transform, Load) processes

- Data mapping and normalization

- Business rules engines

- Master data management

Monitoring & Management:

- Real-time sync status dashboards

- Error alerting and logging

- Performance analytics

- Audit trails for compliance

Real-World Integration Success Stories

Success Story 1: Mid-Sized Manufacturer

Company: Precision machining, 150 employees, $50M revenue

Challenge:

Salesforce CRM, legacy ERP, and separate QuickBooks for financials created massive inefficiencies. Sales closed orders that production couldn't fulfill. Invoicing lagged shipments by weeks.

Solution:

SyncMatters connected Salesforce → ERP → QuickBooks with bidirectional sync and automated workflows.

Results:

- Manual reconciliation reduced by 75%

- Cash flow timing improved through faster invoicing

- Order-to-production cycle time cut by 40%

- ROI achieved in 9 months

- CFO calculated revenue recovery of hundreds of thousands per quarter

Success Story 2: Food & Beverage Manufacturer

Company: Multi-location food manufacturer with strict FSMA 204 compliance requirements

Challenge:

Traceability data scattered across production systems, quality databases, and paper records. Audit preparation required weeks of manual data compilation.

Solution:

Integrated quality management system, shop floor data collection, and ERP to provide complete lot genealogy and automated compliance reporting.

Results:

- Audit preparation time reduced from 3 weeks to 2 hours

- 100% traceability from raw materials to finished goods

- Recall readiness improved dramatically

- Retailer compliance requirements met consistently

- Avoided estimated $500K+ in potential compliance penalties

Success Story 3: Custom Equipment Manufacturer

Company: Configure-to-order manufacturer, 200 employees

Challenge:

Engineering data in PLM system never properly synced with production. BOMs were manually re-entered, leading to frequent errors. Engineering changes often didn't reach shop floor in time.

Solution:

PLM → ERP integration with engineering change control workflows and automated BOM synchronization.

Results:

- BOM errors reduced by 92%

- Engineering change cycle time cut by 60%

- Production delays from incorrect specifications eliminated

- Customer satisfaction scores increased 31 points

- Estimated savings: $400K annually

Building the Business Case for Integration

Securing budget and executive support for integration projects requires a compelling business case. Here's a framework for quantifying the value:

ROI Calculation Template

Step 1: Quantify current hidden costs

| Cost Category | Calculation | Annual Amount |

|---|---|---|

| Manual data entry | Hours/week × staff count × hourly rate × 52 weeks | $________ |

| Inventory carrying costs (excess) | % overstock × average inventory value × carrying rate | $________ |

| Stockout/expedite fees | Incidents/year × average cost per incident | $________ |

| Production downtime | Hours/month × cost per hour × 12 months | $________ |

| Order errors/rework | Error rate × order volume × avg cost to fix | $________ |

| Delayed billing | Days delay × daily revenue × opportunity cost | $________ |

| Compliance near-misses | Audit prep time × hourly cost + risk premium | $________ |

| Strategic missed opportunities | Conservative estimate of lost optimization | $________ |

| Total Annual Hidden Cost | Sum of above | $________ |

Step 2: Estimate integration investment

| Investment Component | Estimated Cost |

|---|---|

| Integration platform/middleware subscription | $________ (annual) |

| Implementation services | $________ (one-time) |

| Data migration and mapping | $________ (one-time) |

| Training and change management | $________ (one-time) |

| Ongoing support and optimization | $________ (annual) |

| Total First-Year Investment | $________ |

Step 3: Project benefits (conservative)

| Benefit Category | Improvement | Annual Value |

|---|---|---|

| Labor hours saved | % reduction × current cost | $________ |

| Inventory optimization | % reduction in excess × carrying cost | $________ |

| Downtime reduction | Hours saved × cost per hour | $________ |

| Error reduction | % improvement × current error cost | $________ |

| Revenue acceleration | Days faster billing × opportunity cost | $________ |

| New capacity | % increase × revenue per unit capacity | $________ |

| Total Annual Benefit | Sum of above | $________ |

Step 4: Calculate ROI

First-Year Net Benefit = Total Annual Benefit - Total First-Year InvestmentFirst-Year ROI = (Net Benefit / Investment) × 100%Payback Period = Investment / (Monthly Benefit) months

Typical Integration ROI Benchmarks

Based on 150+ manufacturing implementations analyzed:

| Company Size | Typical Investment | Annual Benefit | ROI | Payback |

|---|---|---|---|---|

| Small ($5-15M revenue) | $35,000 - $75,000 | $200,000 - $500,000 | 300-600% | 2-5 months |

| Mid ($15-75M revenue) | $75,000 - $200,000 | $500,000 - $2M | 300-900% | 2-6 months |

| Large ($75M+ revenue) | $200,000 - $500,000 | $2M - $10M+ | 400-1,500% | 2-4 months |

How SyncMatters Helps Manufacturing & Distribution Companies

SyncMatters specializes in connecting ERP systems with the broader technology stacks that manufacturing and distribution companies depend on.

Our Manufacturing & Distribution Expertise

Deep industry knowledge:

Our team understands the unique workflows, compliance requirements, and operational challenges facing manufacturers and distributors. We don't just connect APIs—we optimize business processes that drive profitability.

Proven integration experience:

With 10,000+ successful app installations and extensive experience integrating leading ERP platforms including SAP, Oracle, NetSuite, Sage X3, Epicor, and Infor, SyncMatters delivers tested, reliable connections.

Comprehensive service offerings:

- Custom Integrations — Middleware connecting your ERP to CRM, MES, WMS, quality systems, and more

- Data Migration — Expert-led migration when upgrading or consolidating ERP systems

- HubSpot Integration — Seamless connection between CRM and ERP for sales-to-production visibility

- Implementation Services — Strategic guidance on integration architecture and phased rollout

- Ongoing Support — Continuous monitoring, optimization, and enhancement of your integrated workflows

Our Approach

Discovery and assessment:

We map your current technology stack, identify cost leakage points, and design integration architecture addressing your specific challenges and priorities.

Phased implementation:

We implement integrations in priority order, delivering value quickly while building toward a fully connected operation. Each phase is thoroughly tested before proceeding.

Training and enablement:

We ensure your team is equipped to use integrated systems effectively, with role-specific training and documentation tailored to your workflows.

Ongoing partnership:

We monitor your integrations continuously, proactively addressing issues and recommending optimizations as your business evolves.

Ready to Eliminate Hidden Costs?

Every day without integrated workflows, your manufacturing or distribution company is losing money it doesn't know it's losing. The companies that get integration right don't just survive—they thrive, winning more business, delivering better margins, and scaling with confidence.

Contact SyncMatters today to discuss how integrated ERP workflows can transform your firm's profitability.

Explore more resources:

- View integration case studies

- Learn about data migration

- Calculate your HubSpot ROI

- Read our integration blog

Implementation Roadmap

For companies ready to tackle integration, here's a practical roadmap:

Phase 1: Assessment and Planning (2-4 weeks)

Week 1-2: Current state analysis

- Map all systems currently in use

- Document data flows (current manual and automated)

- Identify pain points and quantify costs

- Survey stakeholders across departments

Week 3-4: Future state design

- Define integration priorities based on ROI

- Design integration architecture

- Select integration platform/approach

- Create implementation timeline

- Secure executive sponsorship and budget

Phase 2: Foundation (4-6 weeks)

Core setup:

- Deploy integration platform

- Establish connectivity to priority systems

- Configure master data management

- Create data mapping specifications

- Build testing environment

Data preparation:

- Cleanse data in source systems

- Standardize coding structures

- Resolve duplicate records

- Define data governance policies

Phase 3: Priority Integrations (6-12 weeks)

Implement integrations in priority order, typically:

Sprint 1: CRM → ERP

- Order flow automation

- Customer data synchronization

- Real-time quote-to-order conversion

Sprint 2: Shop Floor → ERP

- Production data capture

- Real-time WIP visibility

- Equipment status integration

Sprint 3: WMS ↔ ERP

- Inventory synchronization

- Automated stock movements

- Cycle count integration

Sprint 4: ERP ↔ Accounting

- Financial data synchronization

- Automated reconciliation

- Reporting integration

Phase 4: Testing and Validation (2-3 weeks)

User acceptance testing:

- End-to-end workflow validation

- Performance testing under load

- Error handling verification

- User interface testing

Training:

- Role-specific training sessions

- Documentation and quick-reference guides

- Train-the-trainer programs

- Ongoing support plan

Phase 5: Deployment and Optimization (4-8 weeks)

Go-live:

- Phased rollout by department or facility

- Parallel operation period for validation

- Issue resolution and refinement

- Performance monitoring

Optimization:

- Gather user feedback

- Refine workflows based on actual usage

- Add automation opportunities identified

- Measure and report benefits

Phase 6: Continuous Improvement (Ongoing)

Regular reviews:

- Monthly integration health checks

- Quarterly performance analysis

- Annual strategy alignment

- Proactive optimization

Expansion:

- Add new systems as acquired

- Enhance existing integrations

- Incorporate new capabilities

- Scale across new locations

Conclusion

The hidden costs of disconnected ERP systems in manufacturing and distribution are real, substantial, and entirely preventable. From the $312,000 annually wasted on manual data entry to the $180,000 lost to production delays and the strategic blind spots that prevent companies from capitalizing on market opportunities—the price of disconnection compounds every day.

But these costs aren't inevitable. Modern integration technology makes it possible to connect existing systems, automate data flows, and create the real-time visibility that drives operational excellence.

The Bottom Line

Integrated ERP workflows deliver:

- 80-90% reduction in manual data entry freeing staff for value-creating work

- Real-time operational visibility enabling faster, better decisions

- 95%+ inventory accuracy optimizing working capital

- 80%+ reduction in production delays from information gaps

- 85%+ reduction in order errors improving customer satisfaction

- 75% faster month-end close giving finance teams time for strategic analysis

- Audit-ready compliance reducing regulatory risk

- Scalable architecture supporting growth without proportional cost increases

The companies that implement these integrations don't just reduce costs—they build competitive advantages that compound over time. Better data leads to better decisions, which leads to better outcomes, which leads to sustainable growth.

Your Next Step

The question isn't whether your company can afford to integrate. The question is whether your company can afford not to—while competitors who've eliminated these hidden costs continue pulling ahead.

The path forward is clear:

- Assess your current state using the frameworks in this article

- Quantify your hidden costs with the ROI calculation template

- Prioritize integration opportunities based on impact and feasibility

- Partner with integration experts who understand manufacturing workflows

- Implement in phases to deliver value quickly while minimizing disruption

Contact SyncMatters today to start the conversation about eliminating hidden costs and unlocking the full potential of your ERP investment.